-40%

1/4" (6mm) diam carbide with 3/16" round holder for woodturning hollowing tools

$ 1.18

- Description

- Size Guide

Description

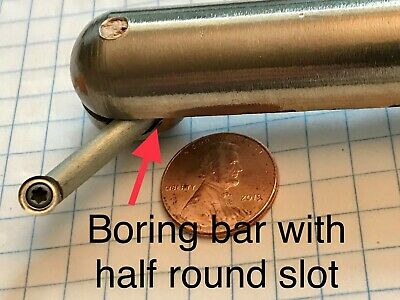

Picture of items are typical, not necessarily exact one you'll receive, but all are new and unused. These tools can be used in hand held or fixed system hollowing tools in place of the existing HSS tool of equivalent size. The round shank tool can also be used in place of the HSS used in most Sorby Hollowmaster type hollowing tools, utilizing a slotted disc to retain the cutter, as well as other various hollowing tools or systems using 3/16" HSS cutters. See example of a Sorby type half round slot. Sorby boring bar not included.See separate listing if you need either a square shanked tool holder, or a larger 1/4" round shank tool.

This holder with new polished and very sharp insert will take the place of most 3/16" round and square HSS inserts used in hollowing rigs. I've used one of these on a Sorby Hollowmaster and Multi-tool, as well as my own hollowing equipment in place of a 3/16" square or rounded HSS insert and often can skip any internal sanding or use of scrapers altogether by using this cutter in both shearing and shear scraping modes. Superior to cutters that rely on scraping alone, this style cutter has a learning curve to it, but the results are typically a superior cut and finish.

Cutting woods with high silica content or root material where dirt is often encountered and you will spend more time resharpening your HSS tools, and less time hollowing. Carbide is an extremely good alternative in this situation even for the bulk of hollowing operations.

Items available:

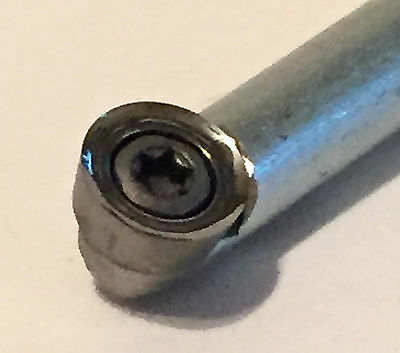

3/16" Round Shank - Complete Tool -

(item includes 3/16" round shank, 6mm cutter and screw, assembled)

This is a round 3/16" diam x 1 1/4" long zinc plated steel shank for this tool. My favorite, it allows tweaking of approach angle in your tooling for optimum results. I typically keep mine at about a 30-40 degree angle, but find that some more aggressive variations seem to work better for softer/harder woods or the part of the form being hollowed.

Replacement items available:

6MM Cutter - Will also fit many other hollowing system tools using 6MM (1/4") diameter cutters. This is a single cutter, order quantity desired. Note: The price on these seems to be going up on each order, but hopefully is stable now. Recommend ordering a spare with any tool purchase to avoid price changes and take less shipping. Additional shipping/handling with these is no charge when purchased along with a complete tool at full shipping cost.

Screw for 6MM Cutter - Will also fit many other hollowing tools using 6MM (1/4") diameter cutters utilizing 2.5-.45 thread pattern. T8 torx. . This is a single screw, order quantity desired. Additional shipping/handling with these is no charge when purchased along with a complete tool at full shipping cost.

Shipping:

US Only: If you order more than one complete tool, the extra cost of shipping for additional complete tools is only {{detail_product_description}}.50. Extra cutters or screws ordered at the same time as a complete tool incur no additional shipping costs. If this doesn't add up correctly, as me for an invoice or I'll credit your paypal acct accordingly.

Outside US: Orders using the eBay Global Shipping Program will ship out individually, and items cannot be combined for shipping discounts.

Thanks and happy turnings!

Disclaimer:

Buyer assumes all risk and responsibility for use of this item.

Woodturning is an inherently dangerous activity and poses risk of damage to the work piece, tool or injury to self from use inconsistent with intended use.

Always check that the tool and other equipment are in proper working order prior to use.

Always maintain as little overhang of a tool from a tool rest as is possible to reduce the forces transmitted along the shank of tool.

Be sure orientation of tool minimizes likelihood of a ‘catch’ with the wood.

For tools without handles, make sure the insertion depth and handle material is sufficiently strong and designed to carry the typical forces to be applied to the tool.

Exercise care and preplanning to assure no materials (rocks/sand/nails/etc) are in the wood which could result in a sudden grabbing of the tool.